IQS – Pressure Vessels

Serving the OEM Market and the Manufacturing Industry

Editorial by Industrial Quick Search

https://www.iqsdirectory.com/articles/pressure-vessel.html

Introduction

This article presents all the information you need to know about Pressure Vessels. Read further and learn more about:

- What are Pressure Vessels?

- Types of Pressure Vessels

- Materials Selection for Pressure Vessels

- Design of Pressure Vessels

- Quality Testing and Inspection of Pressure Vessels

- And much more…

Chapter 1: What Are Pressure Vessels?

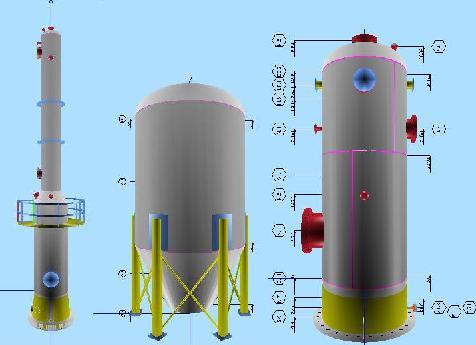

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as petrochemical, oil and gas, chemical, and food processing industries. Equipment such as reactors, flash drums, separators, and heat exchangers are examples of pressure vessels.

Each pressure vessel must be operated within its design temperature and pressure, which is the pressure vessel‘s safety limits. The design, construction, and testing of pressure vessels are extensively carried out by knowledgeable personnel and are governed by regulations because the accidental release and leakage of its contents is a danger to its surrounding environment. Some of the well-known standards are the American Society of Mechanical Engineers Boiler and Pressure Vessel Code (ASME BPVC) Section VIII, and the American Petroleum Industry (API) 510 Pressure Vessel Inspection Code.

Chapter 2: Types of Pressure Vessels

Pressure vessels may be classified according to their purpose or geometry.

Types of Pressure Vessels According to its Purpose

- Storage Vessels. Storage vessels are used to hold liquids and gases for industrial purposes. The vessel may be used to contain fluids in a later process, or for storing finished products such as compressed natural gas (CNG) and liquid nitrogen. Carbon steel is the most commonly used material for storage tanks.

CLICK HERE TO READ ENTIRE ARTICLE